INTRODUCTION

Fabricast offers a complete line of silver graphite leaf and plunger brushes. These assemblies can be used to replace worn brushes on Fabricast slip rings or for other applications on which the customer feels they would be applicable. Our engineers will specify the best brush grade for both Fabricast built slip rings and for customer applications.

The following chart gives some basic information on the most common brush contact materials.

| Grade Number | Composition | Recommended Surface Speed |

Carrying Capacity |

| FAG 180 | 80% Silver 20% Graphite |

Up to 3500 feet per minute |

250 amps per square inch |

| FAG 180A | 80% Silver 20% Graphite plus MoS2 |

Up to 3500 feet per minute |

250 amps per square inch |

| FAG 150 | 50% Silver 50% Graphite |

Up to 6000 feet per minute |

100 amps per square inch |

| FAG 150A | 50% Silver 50% Graphite plus MoS2 |

Up to 6000 feet per minute |

100 amps per square inch |

| FAG 193 | 93% Silver 7% Graphite |

Up to 250 feet per minute |

300 amps per square inch |

Fabricast grade FAG180 is the low noise level grade used for all standard slip rings. In general, a noise level of approximately 1 microvolt for each milliampere of current flow can be accomplished depending on the speed of the unit and quantity of brushes per ring.

Fabricast grade FAG150 is the highest surface speed grade: however, noise levels are slightly higher than FAG180. Brush life is approximately twice that of FAG180. It is recommended when brush life is critical and/or surface speed is high. Low noise can be achieved with multiple contacts per ring.

Fabricast grade FAG193 has highest current carrying capacity; however, it is limited to a surface speed of 250 ft. per minute.

Fabricast grades FAG180A and FAG150A contain molybdenum disulfide in addition to silver and graphite. This additive is required for operation in altitude, vacuum, and inert environments. Other characteristics remain the same.

PLUNGER TYPE BRUSHES Download printable PDF of this page

Plunger type brushes consist of a brass holder with cap, a copper or BeCu buss assembly, and a spring loaded silver graphite plunger brush. Both holder and buss are tin plated. Brush holders are most commonly press fit into a dielectric brush block or soldered/brazed to a buss which is then bolted to the brush block.

2.5 AMP CAPACITY • 3/32” SQUARE

The following chart shows the different plunger brush part numbers for specific brush sizes and brush grades. Download printable PDF of this page

| Plunger Brush Part Number Chart | |||||

| Brush Size | Brush Grade | ||||

| FAG 180 | FAG 150 | FAG 180A | FAG 150A | FAG 193 | |

| 3/32″ Square | 1072-1 | 1072-5 | 1072-11 | 1072-10 | 1072-14 |

| 1/8″ Square | 1072-2 | 1072-6 | 1072-13 | 1072-12 | 1072-15 |

| 3/16″ x 1/4″ | 1913-1 | 1913-2 | 1913-3 | 1913-4 | 1913-5 |

| *1/4″ x 1/2″ | 1092003 | 1092003-31 | 1092003-29 | 1092003-27 | 1092003-25 |

| **1/4″ x 1/2″ | 1991-1 | 1991-2 | 1991-3 | 1991-4 | 1991-5 |

* For use with brush holder P/N 1092006

** For use with brush holder P/N 1092012

For complete information on the different plunger brushes and holders available please download relevant catalog pages or request a Fabricast catalog by phone, Email, or by completing the Request For More Information Form.

LEAF TYPE BRUSHES Download printable PDF of this page

Leaf springs for Fabricast leaf type brushes are made of beryllium copper alloy #25. The leaf springs are heat treated and tin plated. The silver graphite brush contacts are soldered onto the leaf springs.

BRUSH .040 WIDE • BRUSH MATERIAL – FAG 180 (80% AG – 20% C) • LEAF MATERIAL – BECU

5 AMP CAPACITY • DOUBLE BRUSH

BRUSH .040 WIDE • BRUSH MATERIAL – FAG 180 (80% AG – 20% C) • LEAF MATERIAL – BECU

5 AMP CAPACITY • SINGLE BRUSH

BRUSH .090 WIDE • BRUSH MATERIAL – FAG 180 (80% AG – 20% C) • LEAF MATERIAL – BECU

OPTION: Opposite hand assemblies available. Optional brush location shown in phantom.

BRUSH .090 WIDE • BRUSH MATERIAL – FAG 180

(80% AG – 20% C) • LEAF MATERIAL – BECU

BRUSH .090 WIDE • BRUSH MATERIAL – FAG 180

(80% AG – 20% C) • LEAF MATERIAL – BECU

All leaf type brushes illustrated above are specified with FAG 180 brush contact material. For description of optional brush contact materials see catalog page 14.

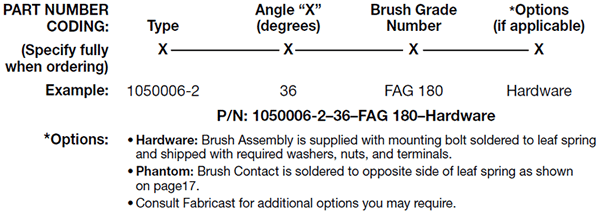

Determination of Angle “X”:

Angle “X” will be supplied by our engineering department for all Fabricast slip ring replacement brushes. For other applications specify angle “X” so that in free state BeCu leaf spring (without brush contact material) would just touch ring surface. This method defines a good starting point for proper brush pressure in most applications. NOTE: Angle “x” does not apply to types 1799, 1120051, and 8115.

For complete information on the different leaf brushes available please download relevant catalog pages or request a Fabricast catalog by phone, Email, or by completing the Request For More Information Form.